Integrity and safety

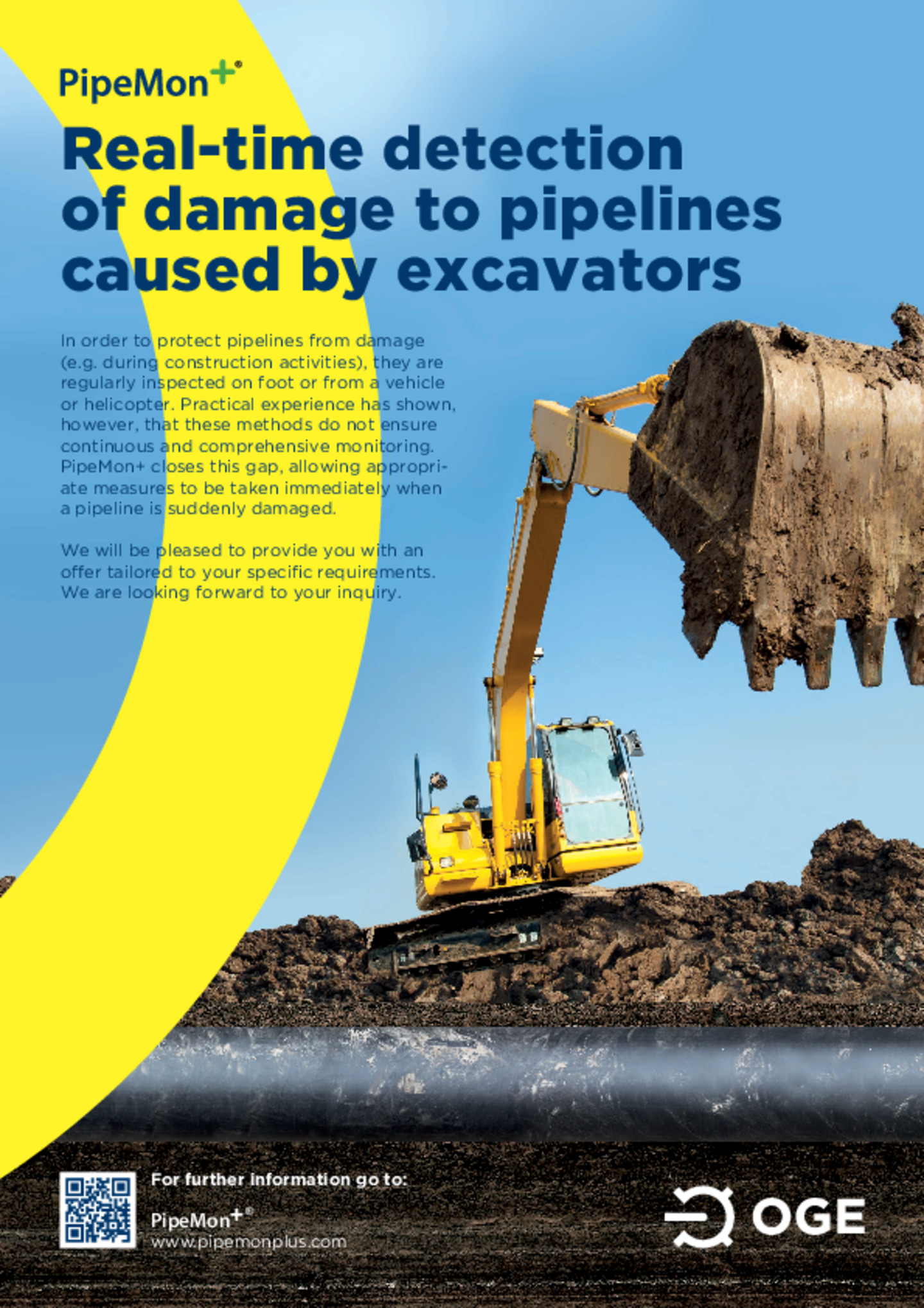

Real-time detection of damage to pipelines caused by excavators

In order to protect pipelines from damage (e.g. during construction activities), they are regularly inspected on foot, from a vehicle or helicopter. Practical experience has shown, however, that these methods do not ensure continuous and comprehensive monitoring. PipeMon+® closes this gap, allowing appropriate measures to be taken immediately when a pipeline is suddenly damaged.

Concept

- OGE has developed a pipeline monitoring method based on the principle of cathodic protection (CP)

- When a cathodically protected pipeline is damaged by construction equipment (excavator, drill, rotary cultivator, etc.), the protective current distribution on the pipeline changes

- Using appropriate sensors and special analysis methods, these events can be detected in real time

Approach

- Sensors are installed approx. every 20 kilometres along the pipeline (network-independent power supply via marker posts with solar panels)

- Sensors continuously measure current and potential (10 times per second)

- If there is contact between an excavator and the pipeline, the operating personnel are alerted

- A pipeline operations team member may be scheduled to site to check the reported excavator contact

Areas of Application

- Temporarily during construction work and when new loop line is constructed

- Permanent for selected networks (e.g. areas with very high protection requirements)

Benefits

- Protection of man and the environment

- Protection of asset and security of supply

- Compensation by party that has caused the damage

- Low investment costs due to use of existing infrastructure

- Additional information on the condition and effectiveness of the cathodic protection (CP) system of the monitored pipeline

- Extended CP monitoring intervals