Information on pipelines

Before you start your construction work: Request free pipeline information.

(Only in German.)

Our customers need to get their gas punctually in the ordered quantity and the desired quality at all times. To make sure they do, we keep our infrastructure fully up to date. This includes not only our 12,000-km pipeline network but also our compressor stations.

We are planning to expand our gas transmission system to include a new pipeline from Etzel via Wardenburg to Drohne. It will consist of two sections, one from the gas storage facility in Etzel to the compressor station in Wardenburg (EWA), and the other from Wardenburg to Drohne (WAD). The EWA section of the roughly 150-kilometre pipeline will have a diameter of 1200 mm, while the WAD section will have a diameter of 1000 mm. Both sections will run parallel to the existing NETRA (Norddeutsche Erdgas-Transversale) pipeline No. 59 and the "Werne-Wardenburg" pipeline No. 58. Together they will provide the capacities needed to move regasified LNG landed at the Wilhelmshaven terminal into the German pipeline transmission system. The Etzel-Wardenburg-Drohne natural gas pipeline will thus contribute significantly to the security of supply in Germany and the Netherlands.

The existing pipelines No. 59 and No. 58 are unable to move all of the volumes from Etzel into the downstream natural gas network. The new Etzel-Wardenburg-Drohne (EWA and WAD) construction project will help to ensure nationwide supply.

Both sections will only use pipes that are also certified for the transportation of hydrogen.

According to the Gas Network Development Plan (Gas NDP), the EWA pipeline section is scheduled for completion by the end of 2026. Preparations for drawing up the approval documents were started at the end of 2022. The planning approval procedure is planned for 2024, and construction will commence at the end of 2024.

According to the Gas NDP, the WAD pipeline section is scheduled for completion by 2027 at the latest. Preparations for the approval documents were started at the end of 2022. The planning approval process is planned for 2024 with construction due to start in 2025.

Each pipeline section will require a separate planning approval process, for which the authorities in the respective federal state will be responsible. OGE plans to commission the EWA section by the end of 2025 and the WAD section by the end of 2026.

After review by the Federal Network Agency, OGE has continued with its plans for the HeiDo and MaHei pipelines. The two projects will ensure a secure and reliable gas supply in the region and are in keeping with the currently valid Gas Network Development Plan (NDP) 2020-2030 and the draft Gas NDP 2022-2032.

The original HeiDo project (Gas NDP 2018 ID 436-02) was split in two. Under the new plans, a pipeline will now be built from Marbeck to Heiden (MaHei pipeline, Gas NDP 2020 ID 436-02a). The approximately 1.5 km MaHei pipeline (DN 600, DP 100) will run from the connection point with the ZEELINK pipeline near Marbeck to the GPRM station to be built in Heiden where it will tie into the existing pipeline No. 27/1. Both the MaHei pipeline and the Heiden-Borken GPRM station are needed for the conversion of the Sonsbeck-Dorsten market area from L-gas to H-gas.

The other project is a DN 500 / DP 100 pipeline between Heiden and Dorsten (HeiDo, Gas NDP 2020 ID 436-02b). The approximately 17 km pipeline will run from the end point of the Marbeck-Heiden pipeline and the Heiden-Borken GPRM station to Dorsten and use the existing HeiDo route.

The next step now is to apply for planning approval for the two natural gas pipelines by the end of 2023. The public will again be involved in the planning process which will also include a Dialogue Market in the region. The construction work for both pipelines is scheduled to start and be completed in 2026.

Background

Following on from the changes to requirements in the current Gas NDP 2020-2030, project needs in the Westmünsterland region have also changed. The original HeiDo project (Gas NDP 2018 ID 436-02) was therefore split into two projects, HeiDo and MaHei. As a result, there was no longer any justification for the gas pipeline from Heiden to Dorsten (HeiDo pipeline), for which planning approval had been sought as part of the Gas NDP 2018-2028. The application for planning approval filed with the Münster district government was therefore withdrawn in December 2021.

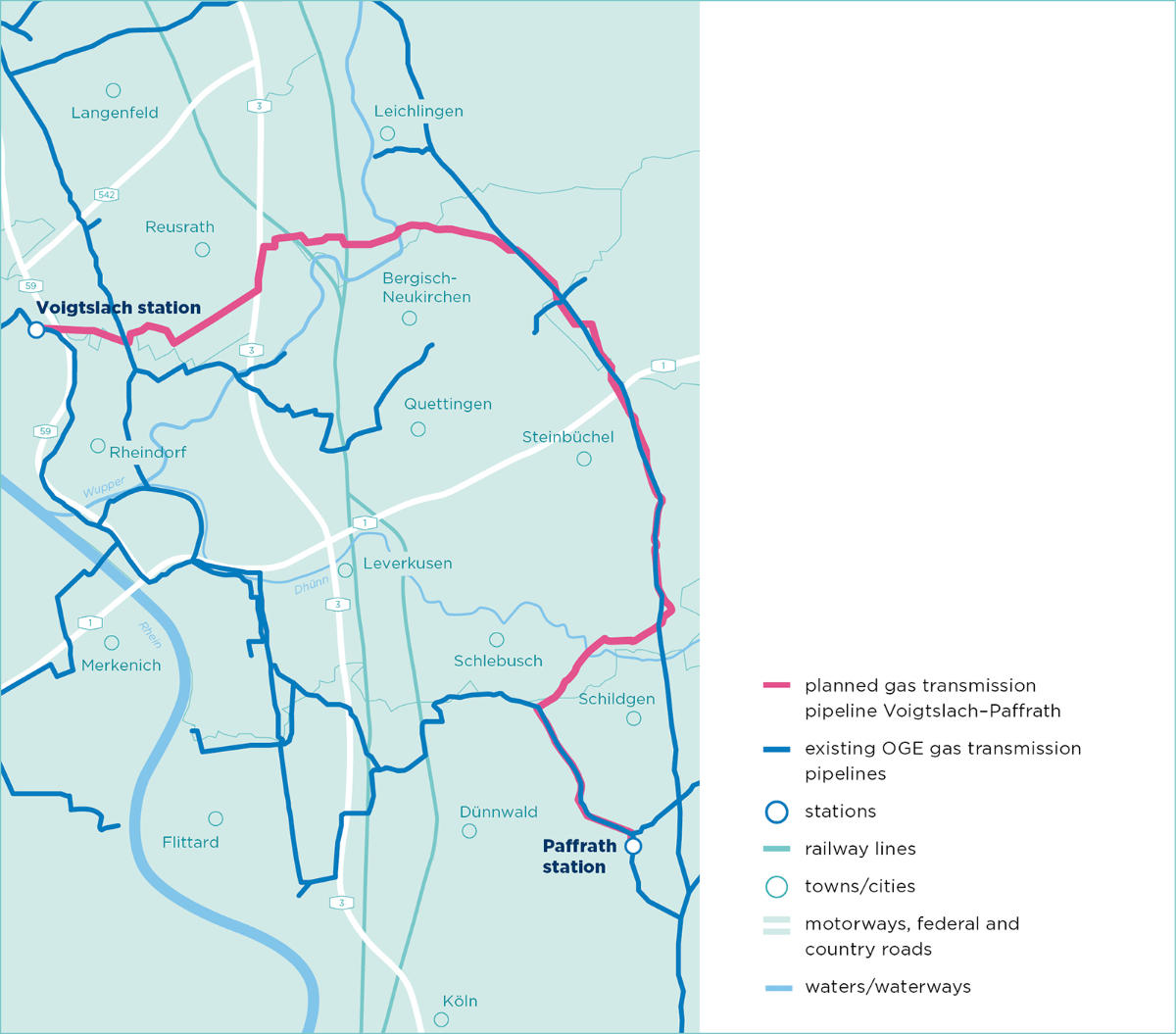

We are planning to expand our supra-regional gas transmission system to include a new high-capacity pipeline from Voigtslach to Paffrath. The almost 24-kilometer-long pipeline will have a diameter of DN 900 and a wall thickness of 12.9 mm and be designed for an operating pressure of up to 70 bar. Construction is scheduled to start in the first quarter of 2021 and will be completed by the end of 2022.

The Nordrheinische Erdgastransportgesellschaft mbh & Co. KG (NETG) is the operator of the pipeline of the same name extending from Elten on the Dutch border to Bergisch Gladbach.

Its owners are Essen-based Open Grid Europe GmbH (OGE) and Dortmund-based Thyssengas GmbH who hold 50% each.

This new link will allow the urgent conversion of the regional and municipal gas grids from low-calorific (L-gas) to high-calorific natural gas (H-gas) in Leverkusen, Cologne and the surrounding communities from the first quarter of 2023. The construction project serves to secure supplies to residential consumers and industry.

TENP III comprises a total of three new pipeline sections built in the existing TENP I pipeline corridor as well as one new station. The new pipeline sections, which are needed for technical reasons, will ensure security of supply in Baden-Württemberg as well as in Switzerland and Italy. The affected sections of TENP I are currently not in service, so the gas flows are being diverted.

Apart from a section between Hügelheim and Hüsingen, the two TENP I sections from Schwarzach to Eckartsweier in Baden-Württemberg and from Mittelbrunn to Klingenmünster in Rhineland-Palatinate are also affected by the planned work.

On all three sections of the route, the pipeline will be replaced within the same right of way. The TENP I pipes will be removed first, and the new TENP III pipes will then be installed almost entirely in the existing corridor.

The project also includes a new pig trap station near Au am Rhein. 'Pigs' are devices used for cleaning and especially for inspecting pipelines. They are introduced into the pipeline via pig traps, which are the main component of a pig trap station.

A total of five different planning approval procedures with public participation are now underway for the three pipeline sections and the pig trap station. Geographically, two different approval authorities are responsible for the section from Schwarzach to Eckartsweier. Construction along this section of the route is due to start in early 2023 with completion scheduled for 2024/2025.

For the section from Mittelbrunn to Klingenmünster, the Structural and Approval Directorate of Northern Rhineland-Palatinate issued its planning approval decision on 25 October 2022. Construction work has been underway here since April 2023. Before that there was preparations for construction work, such as the establishment of the working strip and logging work.

Further information on the project can be found in the info brochure (only in German).

Information on the work on the individual sections Mittelbrunn - Klingenmünster (Rhineland-Palatinate), Schwarzach - Eckartsweier (Baden-Württemberg) and Hügelheim - Hüsingen (Baden-Württemberg) can be found on the German website.

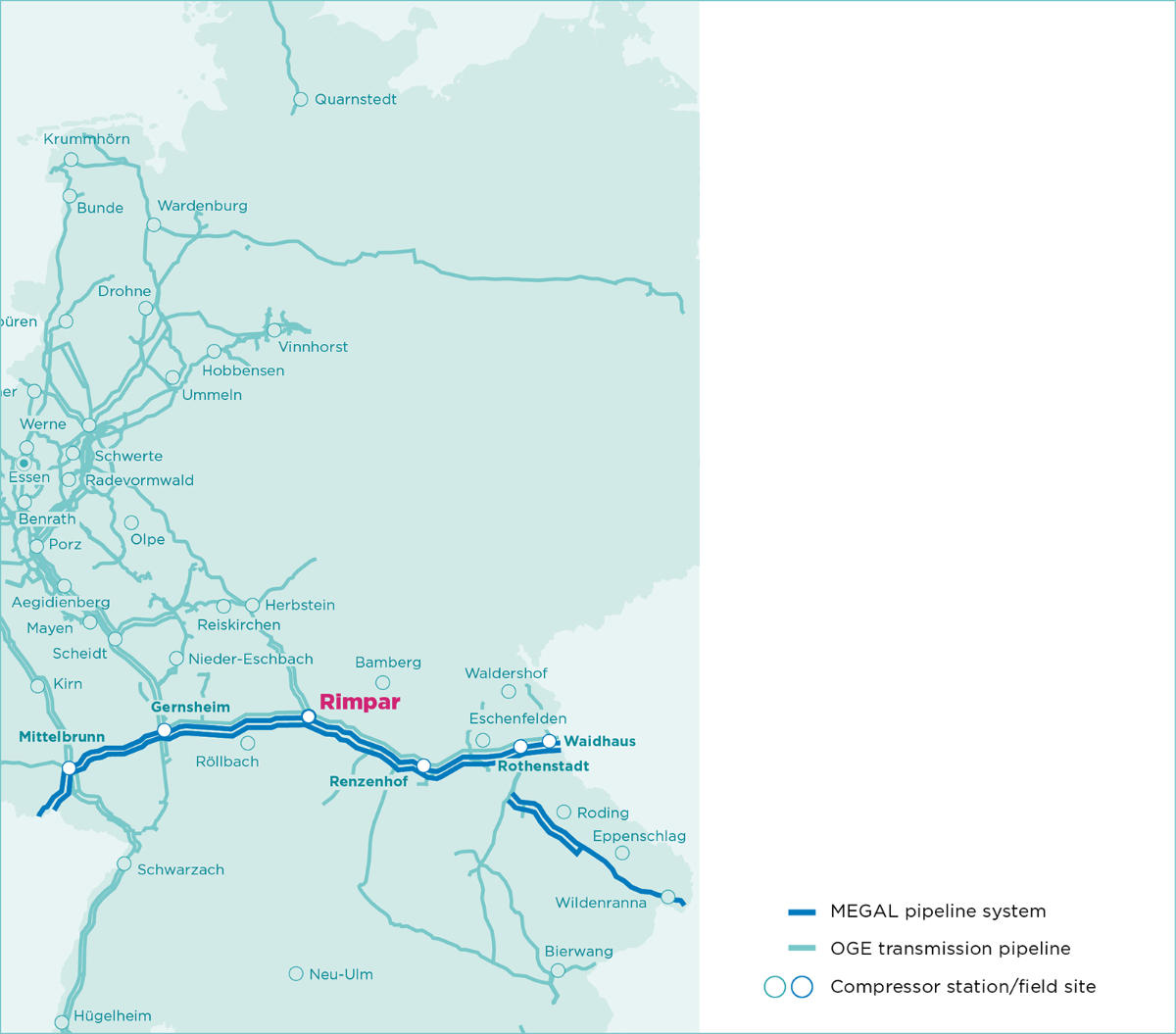

The new Rimpar compressor station (Bavaria) will be built in the immediate vicinity of the existing Rimpar compressor station to compress gas primarily from MEGAL I & II. In addition, it will be used to compress volumes to be shipped to or from the north. It will connect pipeline nos. 51 (MEGAL I) and 451 (MEGAL II), as well as pipeline nos. 55 (OGE), 455 (OGE) and 26 (OGE).

The MEGAL (Mittel-Europäische Gasleitung) pipeline system is operated by a joint venture company established by the two gas transmission system operators Open Grid Europe and GRTgaz Deutschland. MEGAL consists of two axes: MEGAL North, a dual natural gas pipeline stretching for some 460 km from the Czech border to France, and MEGAL South, running from the Austrian border towards Rothenstadt.

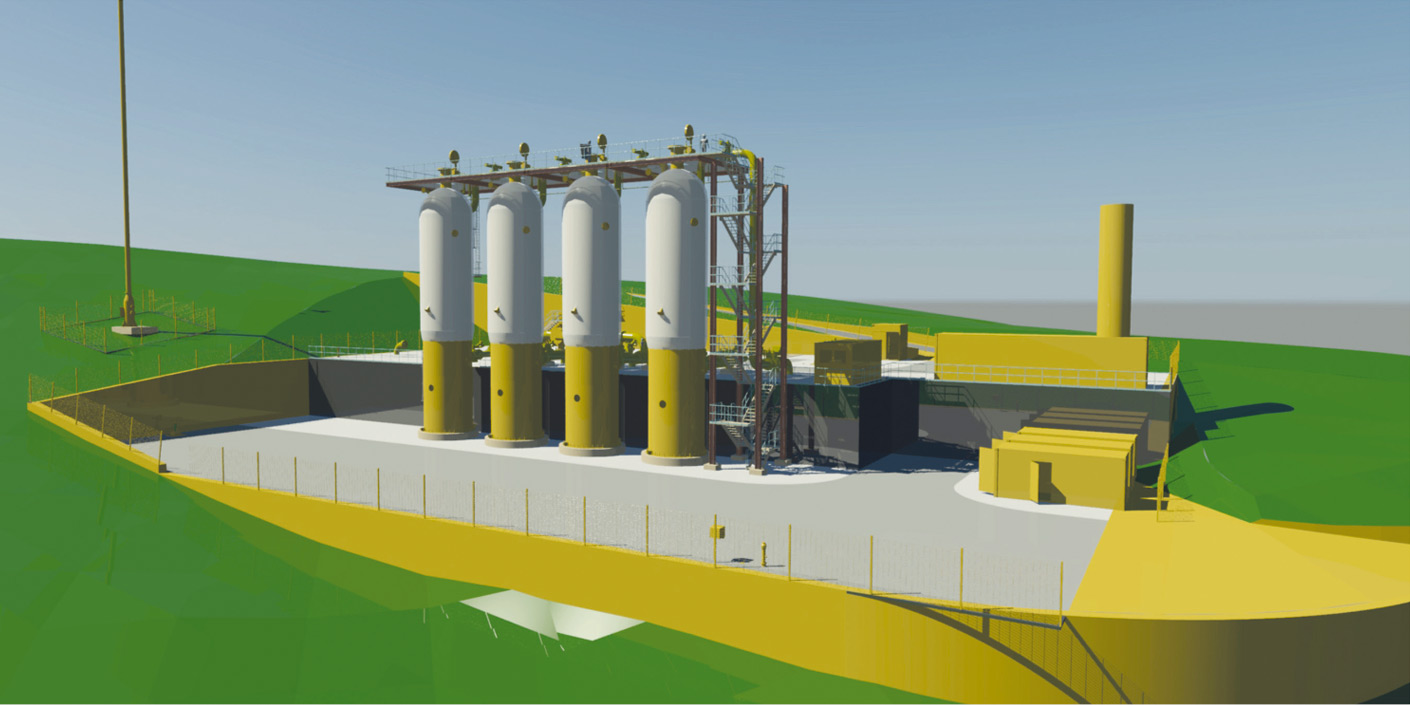

The new compressor station will essentially consist of three new gas turbine-driven turbo compressor units each housed in a separate compressor building with the associated peripheral piping and plant systems, as well as a new supply and fuel gas building to accommodate all necessary auxiliary installations and systems.

Initial preparations for the construction project began in January 2020. The plant is scheduled for completion in 2023.

The 26 km long Wilhelmshaven pipeline link (WAL) was completed in 2022 in just nine months. It enables the reliable transport of natural gas imported via the Wilhelmshaven LNG terminal into the German gas network. Germany is thus less dependent on Russian energy. The pipes used for construction are hydrogen-compatible and thus serve as cornerstones for a future hydrogen economy.

From left: Olaf Lies (Minister of Economics of Lower Saxony), Franz-Josef Kissing (Project Manager OGE), Thomas Hüwener (Member of the Management Board OGE), Morten Höegh (Shipping company Höegh), Christian Lindner (Federal Minister of Finance), Siemtje Möller (Parliamentary State Secretary in the Federal Ministry of Defence), Niels Fenzl (Project Manager Uniper), Olaf Scholz (Federal Chancellor), Stephan Weil (Minister President of Lower Saxony), Holger Banik (Managing Director Niedersachsen Ports), Robert Habeck (Federal Minister of Economics), Christian Meyer (Minister of the Environment of Lower Saxony), Carsten Feist (Mayor of Wilhelmshaven)

Open Grid Europe GmbH (OGE) built a new gas metering and pressure regulating (GMPR) station in Leverkusen-Pattscheid from the end of March 2022 until the beginning of 2023. GMPR stations are an essential part of the gas network. In order to ensure the constant supply of natural gas from the production regions to customers (e.g. municipal utilities), compressor stations are used to raise the pipeline pressure to as much as 100 bar. This pressure had to be reduced before the gas was supplied to the end user, which is one of the reasons why GMPR stations are required.

The GMPR station in Leverkusen-Pattscheid connect OGE's existing gas pipeline No. 12 to NETG's pipeline No. 600. It is needed as part of the switch from L-gas to H-gas, which is scheduled to take place in the Cologne area in 2023. The GMPR station will allow pipeline No. 12 to be supplied with gas from the new pipeline No. 600.

The station operates autonomously, i.e. without on-site personnel, but it will be monitored and controlled from the central grid control room in Essen. It will also be inspected and maintained by specialists at regular intervals.

As part of the conversion of the natural gas pipeline network from L-gas [low-calorific gas] to H-gas [high-calorific gas], OGE had to build a new gas pressure regulating and metering (GPRM) station in the village of Asbeck near the town of Menden. The station is used to feed gas taken from the Werne-Schlüchtern pipeline (line No. 56) into the Beckum-Werdohl pipeline (line No. 17).

The GPRM station consists two identical flow control & meter runs connected by inlet and outlet manifolds. Both runs are fitted with filter separators which are installed outdoors while the equipment used for metering, preheating, pressure protection and control purposes is installed inside a building. Line No. 56 has been connected to the station via a new pipeline link (DN 400, approx. 15 m long). Line No. 17 was connected by installing two tees, a gate valve station and another pipeline (DN 400, approx. 10 m long). A new vent line has also been built.

Construction of the new station started in February 2021. 8000m³ of soil and gravel were moved during the construction period. The station was completed in Q4 2021, and the surface restoration work ended in summer 2022.

Our largest construction project in recent years has been the ZEELINK gas transmission pipeline which was commissioned on schedule in May 2021. This new pipeline was needed for the gradual conversion of gas customers from L-gas to H-gas, especially in North Rhine-Westphalia. ZEELINK allows us to connect the regions that are currently still supplied with L-gas to H-gas sources and routes on a permanent basis.

The ZEELINK natural gas pipeline, which is almost 216 km long, stretches from Germany’s border with Belgium near Aachen-Lichtenbusch via Sankt Hubert near Krefeld to Legden near Ahaus in North Rhine-Westphalia. The project also included the construction of a compressor station near Würselen. The new transmission pipeline makes an important contribution to supply security in Germany and also enhances the transmission capacity of the natural gas pipeline network from the north to the south.

ZEELINK is the largest single project in the Federal Network Agency’s Gas Network Development Plan 2015 (Gas NDP). The pipeline provides a connection to the LNG terminal in Zeebrugge and thus contributes to the diversification of natural gas sources and transmission routes to Germany. The name ZEELINK is derived from the Belgian LNG terminal in Zeebrugge. LNG is the acronym for liquefied natural gas.

Commissioning of the ZEELINK gas transmission pipeline in Würselen/North Rhine-Westphalia in May 2021 (from left): Jörg Bergmann (CEO of OGE), Armin Laschet (Premier of North Rhine-Westphalia) and Thomas Gößmann (CEO of Thyssengas)

Given the need for more flexible gas transmission from the north to the south and vice versa, it was decided to build a deodorisation plant on the Trans-Europa-Naturgas-Pipeline (TENP) system. The project was executed jointly by Open Grid Europe GmbH and Fluxys TENP GmbH and was commissioned on schedule in December 2020. The plant is operated by Open Grid Europe GmbH.

The project called for the construction of a plant to remove tetrahydrothiophene (THT) from the gas coming from France. THT is an odorant that is used extensively in the French high-pressure gas pipeline system, but is only added to the German network at the distribution level. It is not used in high-pressure gas pipelines due to the technical requirements during transmission.

Natural gas entering the TENP system at the cross-border interconnection point at Wallbach for transmission from the south to the north may therefore contain different levels of THT. Consequently, for transmission and consumption in Germany, the natural gas must be treated in a way that reduces the THT concentration.

The odorant is removed by fixed-bed adsorption, as is common practice in gas treatment. For this purpose, the natural gas is piped through the deodorisation plant, which essentially consists of a total of four adsorber towers and the necessary ancillary equipment.

Due to the European character of the TENP pipelines, which link up several countries, the deodorisation plant is recognised a Project of Common Interest (PCI) and was therefore eligible for funding by the European Union under the supervision of the Innovation and Networks Executive Agency (INEA). For this reason, it is subject to EU Regulation 347/2013 on the Guidelines for Trans-European Energy Infrastructure (TEN-E Regulation).