Projects

How to produce biomethane from biogenic residues? This is how it works!

Together with our partners New Power Pack, the Jülich Research Centre and the Fraunhofer Institute UMSICHT, we have built and tested a demonstration plant for the production of biomethane as part of the so-called BiRG project. In several steps, biogenic residues are converted into biogas that can be fed into the pipeline system. The plant was commissioned in May 2023.

What are biogenic residues?

Agricultural, municipal and industrial activities generate large quantities of biogenic residues in Germany every year, including, for example, fermentation residues from biogas plants, manure, straw, nutshells, sewage sludge, wood chips and green waste.

The energetic use of these biogenic residues plays an important role in the generation of renewable energies.

Using and spreading these biogenic residues on farmland is increasingly becoming a challenge as it contributes to nitrate pollution of groundwater and is therefore no longer possible without restrictions in every region. Hence, disposal is a costly process for farmers and municipalities.

What is needed is a solution that maximises the local use of these residues as an alternative to costly transportation to regions whose soils are deficient in nitrogen and other nutrients.

Demonstration plant for gas from bio residues

As part of a project named BiRG, the aforementioned partners have built a demonstration plant for the production of biomethane and optimised it in operation. The project was being funded under the German government's 7th Energy Research Programme.

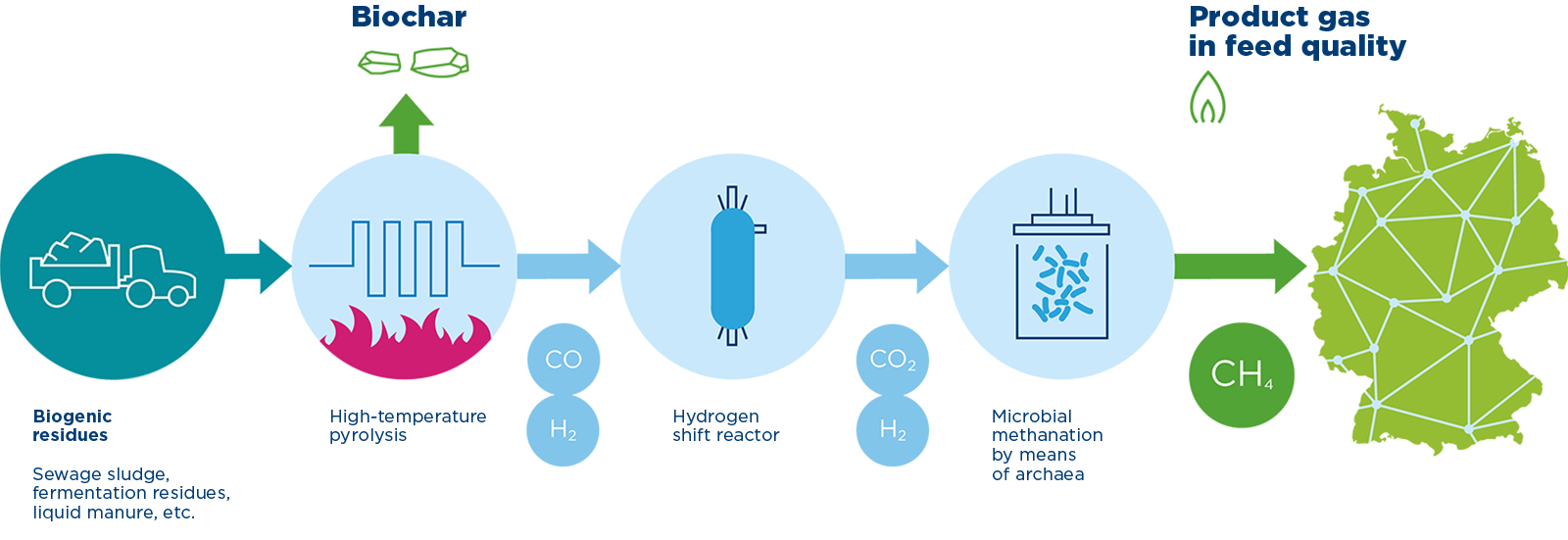

The biogenic residues will be converted into biomethane by means of pyrolysis, followed by a purification stage for the raw gas produced, a water-gas shift reactor and a methanation unit.

In the pyrolysis unit, the biogenic residues are converted into gas and biochar at very high temperatures. The raw gas consists mainly of CH4, CO, CO2 and H2. In the water-gas shift reactor, water vapour is added to the process to turn the CO in the raw gas into CO2 and H2. In the subsequent microbial methanation process CO2 and H2 are then converted to CH4 and water with archaea*. Finally, the CH4 can be fed into the pipeline system.

* Archaea are microorganisms that have a preference for archaic, oxygen-free conditions similar to those on primordial Earth.

BiRG – Three birds with one stone

Generating biogas with the BiRG process helps to reduce greenhouse gases in three ways:

- The resulting biomethane is fed into the natural gas grid, displaces fossil natural gas and thus avoids the emission of fossil CO2: a promising way to produce renewable gases that will help make the energy transition a success.

- The only by-product of the pyrolysis process is biochar. The nutrients bound in biochar (potash, phosphate) can be used as fertiliser and increase soil fertility. Biochar remains in the soil for a long time - up to more than 1000 years. The process therefore has a negative CO2 balance.

- The BiRG process represents an on-site solution to the disposal task of biogenic residues for municipal and farm activities.

Impressions of the commissioning in May 2023

Delivery of biogenic residues

Desulphurisation unit (left) and methanation

Monitoring of desulphurisation during commissioning

Dr Ann-Christin Fleer (OGE), Tim Schulzke (Fraunhofer Institute for Environmental, Safety and Energy Technology UMSICHT)

Strong cooperation between project partners

FLTR: Dr Can Samsun (Forschungszentrum Jülich GmbH), Dr Ann-Christin Fleer, Tim Schulzke, Mazloum Sheikh-Ayoub (New Power Pack GmbH)

Discussion of the next steps of commissioning

FLTR: Dr Ann-Christin Fleer, Dr Can Samsun, Tim Schulzke

Commissioning of the desulphurisation of the raw gas

Dr Ann-Christin Fleer